The use of the blowpipe, in the qualitative and quantitative examination of minerals, ores, furnace products and other metallic combinations / Edited, with emendations, by Dr. Sheridan Muspratt. With a preface by Baron Liebig.

- Plattner, Carl Friedrich, 1800-1858.

- Date:

- 1850

Licence: Public Domain Mark

Credit: The use of the blowpipe, in the qualitative and quantitative examination of minerals, ores, furnace products and other metallic combinations / Edited, with emendations, by Dr. Sheridan Muspratt. With a preface by Baron Liebig. Source: Wellcome Collection.

41/440 (page 17)

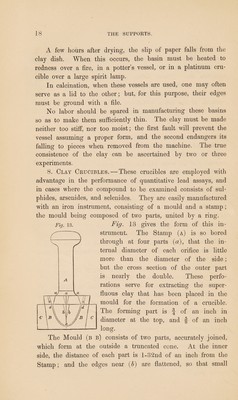

![Fig. 11. 7. Clay Basins. — For quantitative determinations, I employ basins for roasting the Ores, and for the reduction of the lead and tin oxides contained in calcined and uncalcined minerals, &c. These dishes are formed in the following manner: — at first a fire-proof clay is kneaded into a stiff paste with water, and then the forming surfaces of the press, which are of box¬ wood, {Fig. 11, A B,) are rubbed over with a paint-brush dipped in oil. The width of (a), at the upper part, is 7-8ths of an inch, and the depth, 5-16ths; and (b) is constructed of a diameter smaller by the 32nd of an inch. Over the middle of the concavity of the press, place a slip of paper, 3 inches in length, and \ of an inch in breadth, and upon this a small clay ball about j an inch in diameter. Then take part (b) of the press, and stamp it hori¬ zontally upon the clay mass lying in part (a), as far as is required. This being ac¬ complished, the superfluous clay will have Fig. ]2. exuded, and (b) can be removed easily, by careful turning. With a small knife, cut away the clay which is driven out, and then examine the margin, to learn if the basin be uniform throughout, and sufficiently thin. Fig. 12 shews the cross section of one of my basins, which is only l-32nd of an inch thick. If the basin be thicker in one place than in another, (b) must be applied with greater force to that part. When the basin is ready to be taken from (a), the convex part of the press must be carefully removed, and then the slip of paper gently pulled, to extract the clay dish. The utensil, with the slip of paper adhering, is now put away on a stone to dry, and the press is ready for the formation of others. An operator unused to this work will find that sometimes the basins alter in shape after leaving the mould; but this can be remedied by pressing them wdth the fingers upon the convex part (b). 2](https://iiif.wellcomecollection.org/image/b29333714_0041.jp2/full/800%2C/0/default.jpg)